Noi di ESA Robotics crediamo che solo attraverso la continua ricerca sia possibile sviluppare soluzioni in grado di dare ai nostri clienti un reale vantaggio competitivo.

Per questo motivo abbiamo fatto della cultura dell’innovazione la nostra filosofia, e ogni giorno idee e pratiche innovative sono ciò che ci permette di ideare e sviluppare le migliori soluzioni nel campo dell’automazione robotica industriale.

Scopri tutte le soluzioni per l’automazione

Foundry

Certi del valore aggiunto di un prodotto ben finito, offriamo soluzioni su misura per la finitura robotizzata dei vostri pezzi.

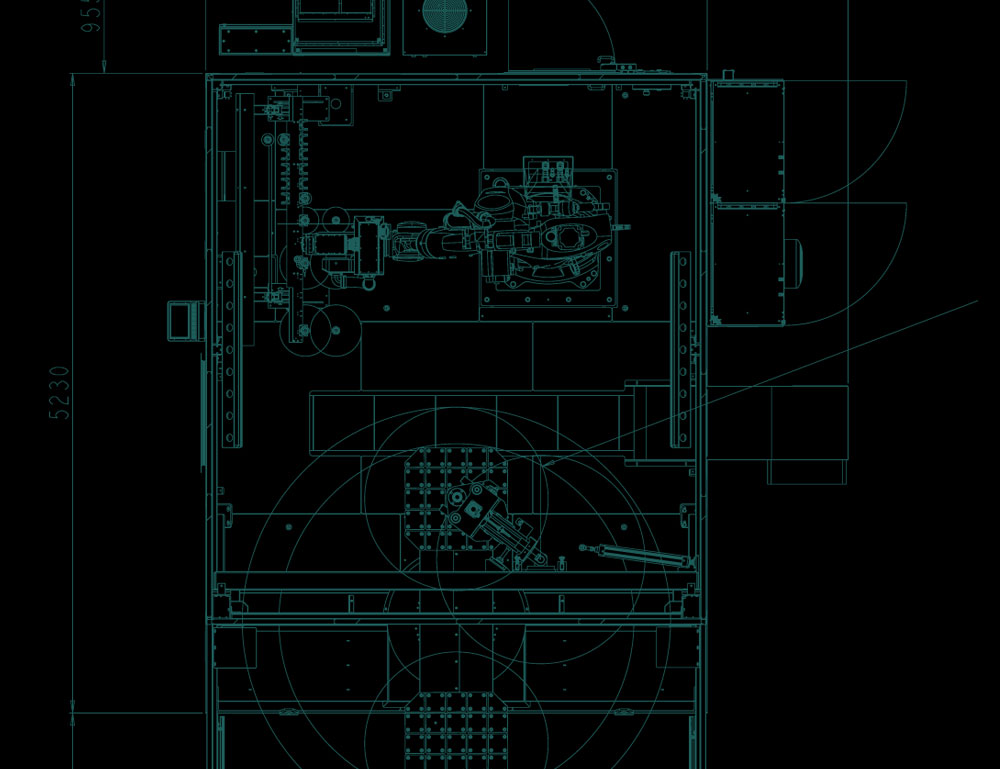

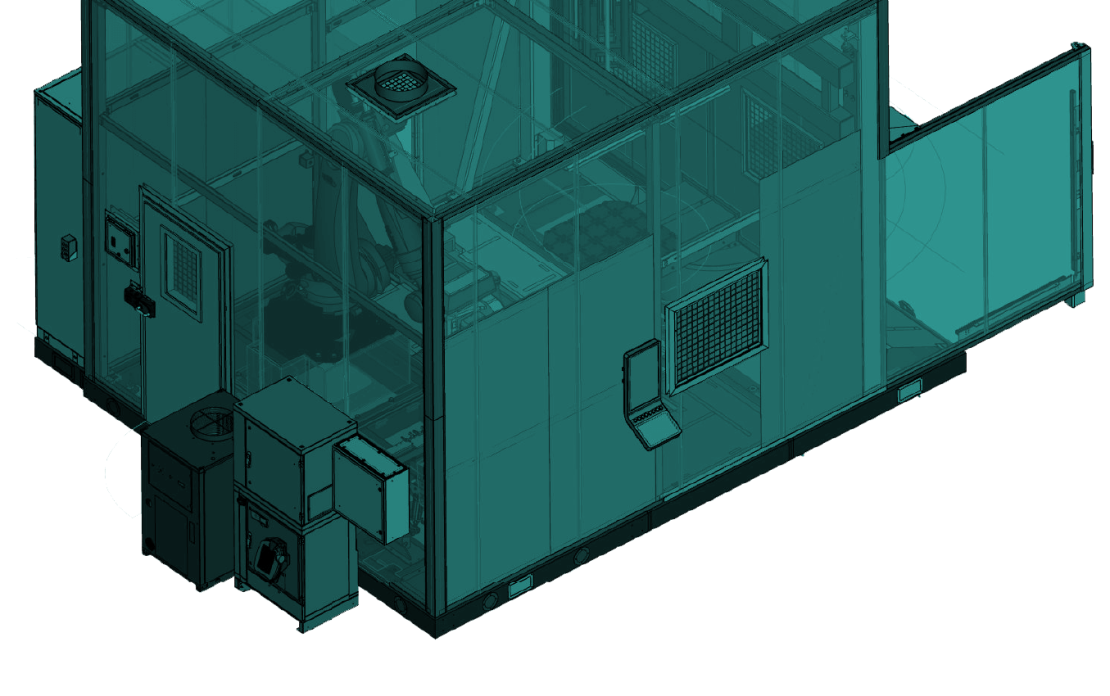

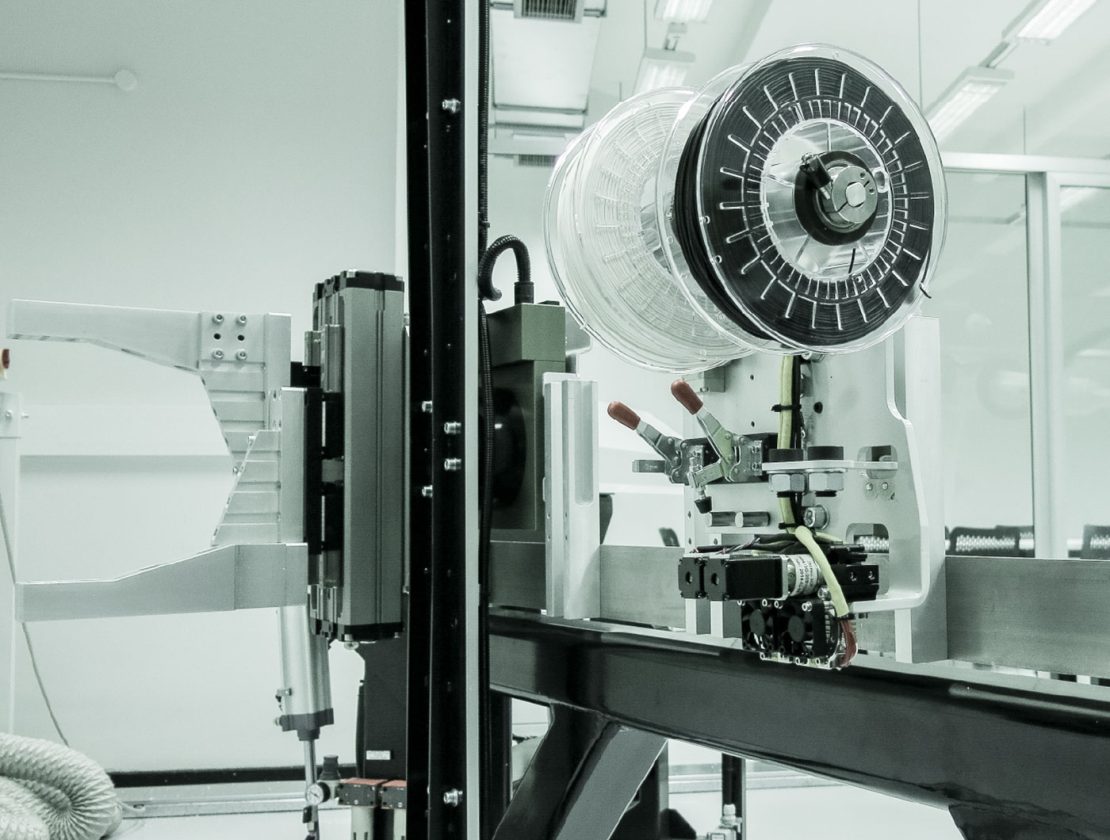

3D Milling

Sistemi robotici completi per la fresatura di un’ampia gamma di materiali: dal polistirolo al legno, dal marmo al granito. I nostri robot danno forma alle tue idee.

Custom Projects

Progettiamo e sviluppiamo soluzioni robotiche per l’automatizzazione dei processi industriali in genere: asservimento, pick & place, movimentazione e infinite altre applicazioni.

Back to

ESA AUTOMATION